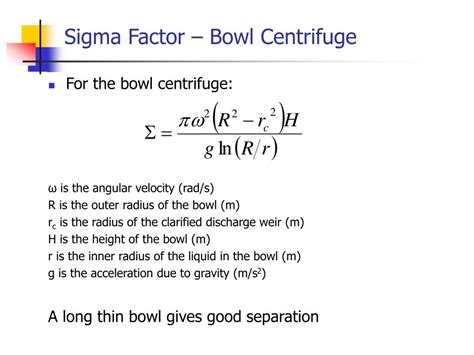

disk stack centrifuge|disk stack centrifuge sigma factor : bulk In process design, many of the important decisions are made based on experience and heuristics. There are many factors affecting process design. Furthermore, processes would be modified in accordance to production, market and environmental demands. A heuristic method available to help design separation process (conical plate centrifuge) is called Douglas (1988) methodology. Douglas methodology uses a three level hierarchical systematic procedure where heuristics ca. What is an autoclave? Autoclaves are also known as steam sterilizers, and are typically used for healthcare or industrial applications. An autoclave is a machine that uses steam under .

{plog:ftitle_list}

Fully autoclavable QuickConnect mop handles and interchangeable mop frames work together for maximum flexibility for cleaning in critical environments. Invest in one handle and various interchangeable frames required for your specific .ACTEON NEWTRON HANDPIECE Handpiece w/out LED, Autoclavable, 2-Tone, Light Grey/ Dark Grey

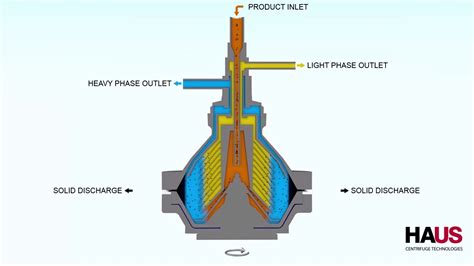

Learn how disc stack separators use centrifugal force to separate liquids and solids with different densities efficiently and accurately. Find out how they are used in various industries and applications.Learn about disc stack centrifuges, the common industrial centrifuges with high centrifugal .In process design, many of the important decisions are made based on experience and heuristics. There are many factors affecting process design. Furthermore, processes would be modified in accordance to production, market and environmental demands. A heuristic method available to help design separation process (conical plate centrifuge) is called Douglas (1988) methodology. Douglas methodology uses a three level hierarchical systematic procedure where heuri.In process design, many of the important decisions are made based on experience and heuristics. There are many factors affecting process design. Furthermore, processes would be modified in accordance to production, market and environmental demands. A heuristic method available to help design separation process (conical plate centrifuge) is called Douglas (1988) methodology. Douglas methodology uses a three level hierarchical systematic procedure where heuristics ca.

A disc stack centrifuge is a specifically designed industrial centrifuge with a stack of cone-shaped discs. The additional surface increases the settling area multi .A disc stack centrifuge is a specific industrial centrifuge that utilizes a stack of conical discs .

Disc Stack Centrifuges are incredible pieces of industrial equipment that have revolutionized the way we separate different substances efficiently. In this comprehensive guide, we will delve into the intricate details of how a Disc Stack Centrifuge works and why it has become an essential tool in numerous industries.Disk stack centrifuges are high-speed centrifuges for the mechanical separation and clarification of mixtures comprising solids and liquids. These machines can be used in a wide range of applications. Due to their special design, disk stack centrifuges work at a higher rotation speed than other centrifuges such as decanters. As a result, the cen -

A typical disk centrifuge stack contains 100 or more disks. The disks reduce the distance that a solid particle must travel before it is separated from the feed. Disk centrifuges range in diameter from 102-762 mm, and are capable of creating forces up to 14,000 times that of gravity. The two diagrams below show how disk centrifuges work.A Disc Stack Centrifuge (a.k.a. Disc Centrifuge) is a high-speed, mechanical centrifuge used for the separation and purification of mixtures comprising of solids and liquids. These machines can be used in a wide range of applications. For example, it can be used in extracting procedures for oil, for basic oil and water separation, and for . In that equation, n is the number of discs, θ is the disc’s half-cone angle (degrees), r 1 and r 2 (meters) are the respective inner and outer radii of the discs, and ω (radians/second) is the angular rotation frequency of the disc-stack centrifuge. The volume of feed material through a centrifuge device per second is Q (m 3 / s).

An MBPX 810 separation system consists of a stainless steel skid with the disk-stack separator and all the auxiliary equipment required for safe and efficient operation. The system is factory tested and ready for operation after connection to the process stream flows and electrical supply.A handful of considerations have a big impact on centrifuge efficiency. Disc Stack Centrifuge Efficiency. A disc stack centrifuge’s efficiency is the centrifuge’s effectiveness in separating the different phases in the process fluid. The centrifuge parameter settings and process fluid properties impact centrifuge efficiency.Using the force of gravity. In essence, a disc stack separator is a settling tank whose base is wrapped around the center line of the bowl. Rapid rotation of separator bowl means that the effect of gravity is replaced by a controllable centrifugal force, or gravitational force known as G-force, that can have an effect up to 10,000 times greater than the force of gravity.

Specially designed disk stack centrifuges are efficient for raw latex processing. The centrifuges have unique features that are conducive to the production of clarified latex fluid. These self-cleaning disc-stack centrifuges can process liquid latex in large quantities at flow rates of up to 50 gallons per minute. Leachate ApplicationThe separator, or disc centrifuge, is a vertically arranged centrifuge. It is used for separating and clarifying liquids. In a disk stack separator, solid-liquid mixtures or liquid-liquid mixtures are separated by centrifugal force. Compared to a decanter centrifuge, the separator differs significantly in its technical design and application.

This high efficiency coupled with the many cost advantages of a compact disk stack centrifuge makes the GEA kytero® an indispensable separator in single-use processes. Processes of 500 liters can be upscaled to 2,000 liters with the same bowl technology. Single-use fed-batch variants may be further upscaled to industrial-size capacities

The CH-range of disc stack separator separator systems is designed with versatility in mind to help you meet separation challenges in various process industries, even those with corrosive, erosive and hazardous environments. Our co-creation methodology and smart pre-engineered systems help reduce cost, time and effort. Each separator is made .Disc Stack Centrifuge - Effect of Flow Rate on Centrate Clarity. Therefore, the operator can reduce the flow rate to achieve better results with the same centrifuge. From the above example, it is clear that a disc stack centrifuge's capacity varies .Disc stack centrifuges uses centrifugal force to separate liquids with a lower concentration of solids and relatively small particle sizes. It is highly suitable for separating two liquid phases as well as a solids phase. Membrane filters typically handle low solids concentrations and capture the smallest particles. Membrane filters typically .

single use disc stack centrifuge

The OFX20 installation is built around a disc stack centrifuge, consisting of a bowl that rotates on a vertical axis, with a stack of conical discs in the centre. Rotating this bowl at high speed creates a controllable centrifugal force that presses the solid particles and water – which are denser – outwards towards the bowl wall, where .

Disc stack centrifuge performance depends on operational parameters that the use of optional equipment can enhance. The following is a detailed list of disc stack centrifuge options and the benefits of each option. We also indicate alternatives that centrifuge customers can provide on their side to extract the same benefits.The disc-stack centrifuge is the most common centrifuge used for separating algae biomass for various applications including algal biodiesel in pilot plants [113, 114]. It consists of a shallow cylindrical bowl spaced between metal discs and is suitable for separating particles with the size of 3–30 μm with very low concentrations of 0.02% .ZK disc stack centrifuge product line is very rich, including DBY260, DBY350, DBY400, DBY470, DBY550, DBY640, DBY730 and other models of ordinary type, food grade and explosion-proof grade and other series to meet the needs of customers in different fields . Each of our product series adopts a unique design and is equipped with an automatic .

The disc-stack centrifuge, as depicted in Fig. 1a, is a highly efficient separation machine that is widely utilized in various industries, including medicine, pharmacy, petrochemicals, and food processing. It operates on the principle of centrifugal separation to achieve two-phase or three-phase separation, offering superior separation .

A disc stack centrifuge separates solids and one or two liquids simultaneously. This is a single continuous process. The centrifuge uses extremely high centrifugal forces to separate the phases. The denser solids subjected to this force move outwards towards the rotating bowl wall. The less dense liquid phases form concentric inner layers.Internationally, disc-stack centrifuges are widely used in oil-water separation on ships. In addition, disc-stack centrifuges are commonly used in biopharmaceutical, food processing, petrochemical .The disc stack centrifuge, is also known as a disc bowl centrifuge or disc stack separator, is a type of centrifuge that has a series of conical discs which provides a parallel configuration of centrifugation spaces. The disc stack centrifuge is used to remove solids (usually impurities) from liquids or to separate two liquid phases from each .The disc stack centrifuge is key for separating large volumes of cells and liquid while harvesting material from a 300L fermentation. Application: solid-liquid separation, 3 phase separations. Features: 2 phase / 3 phase configuration . Equipment .

A mathematical model is proposed to calculate the total separation effectiveness in terms of GT for a disk stack centrifuge taking account of the variation of the centrifugal force with a position in the disk. In practice, the centrifuge ability/force is often referred as Relative Centrifugal Force (RCF) or G number, which is a multiple of the .Disc stack centrifuges in process technology Self-cleaning disc stack cen-trifuges for liquid/solid separa-tion are essential in many tech-nical processes. The rotation speed of disc stack centrifuges is much higher than most other centrifuges in industry. The centrifugal force in a disc stack bowl is apparently stronger than for e. g. in a .

A disc stack separator separates solids and one or two liquid phases from one another using extremely high centrifugal forces. The centripetal force generated by the rotating bowl pushes solids against the periphery of the bowl, while the less dense liquid phases form concentric inner layers. The separation process can be either a discontinuous .

Disc stack centrifuges. New enterprise, extensive knowledge. We are a new company but we boast know-how and long-standing, consolidated experience in the design, production and marketing of disc stack centrifuges. About Us Separators For the separation of mixtures of liquids with different densities and simultaneous elimination of solids .

disk stack separator diagram

100VM5072 VALVE 2 WAY ANGLE 100 KSI www.snap-tite.com/Snaptite_AED/AED_VFT/products/needle_valves/high_pressure_valves_150k/index.html .

disk stack centrifuge|disk stack centrifuge sigma factor